56006 the work doesn’t stop because of our AGM.

Repairs continue following preparatory work carried out by two volunteers yesterday.

The Main Ammeter and Slow speed speedometer had been showing incorrect readings and the Ammeter was functioning intermittently.

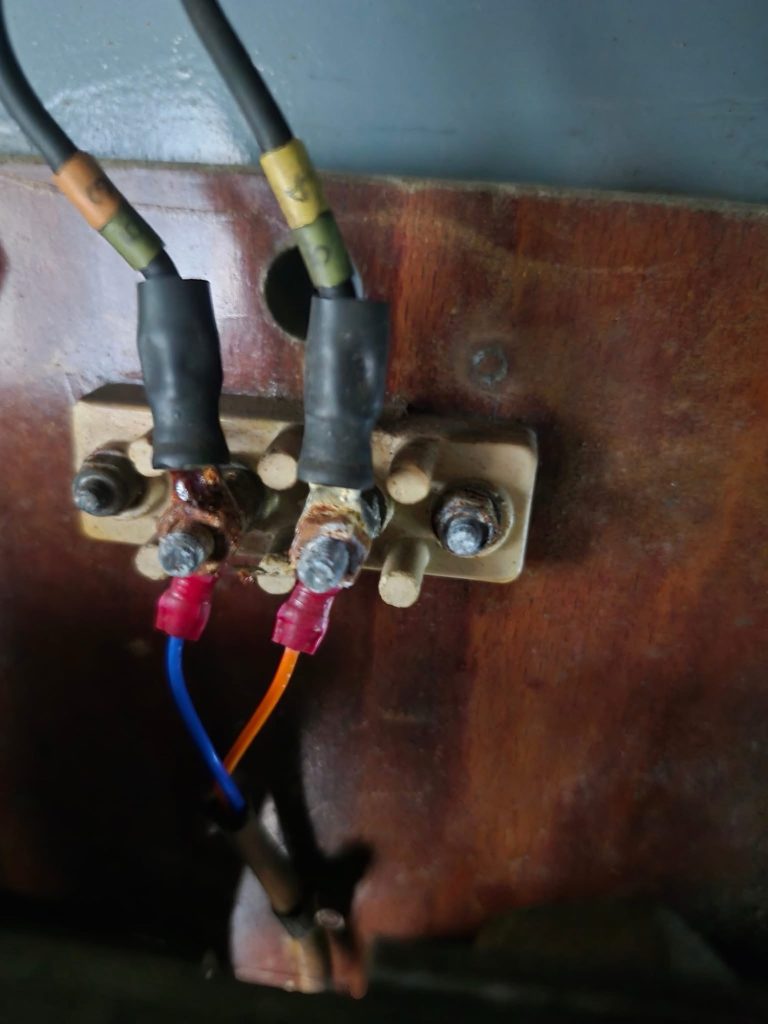

The attached photographs show the work progressing.

Note the panel had to be removed to access the nuts holding the instruments in place.

Also you can see the white marks added to the wires prior to disconnection, so they could be reconnected correctly.

Once all put back in place the loco was started up and checked to see it takes power correctly and that the Ammeter responds correctly.

Further works completed.

The fault finding work into the PEFR fault, had revealed a thermistor( temperature sensor) in the main rectifier was defective and this had been linked out ( bypassed) by a link wire on the main rack panel in the electrical cubicle.

We had obtained a replacement thermistor and prepared to replace the defective sensor.

Unusually the cabling was quite clean and the idents on the cables was easy to identify and trace on the wiring diagram.

Once fitted the Temperature monitoring module displayed a green LED which it hadn’t previously. This means the locos protective system would now function as intended and protect the locomotive if the main rectifier reached excessive temperatures.

These LEDs are very useful to the technical team as they give a visual check that all is well.

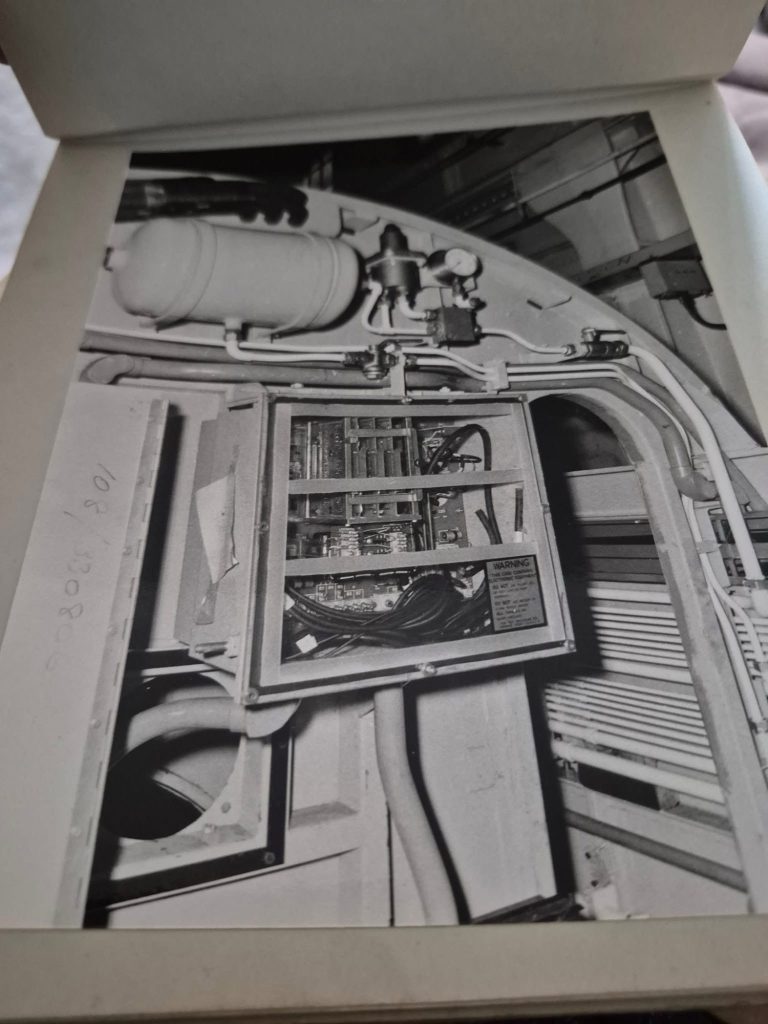

With that in mind a job had been carried out on the battery charge panel. The panel has various LEDs but the transparent panel on the front of the panel wasn’t very clean anymore hence making it difficult to see the important LEDs. ( some before and after photos attached – including a picture of the panel on an official BREL photograph of 56031 when it was brand new in 1977! ) Enjoy.